Heat Reflective Roof Coating: Transform Your Industrial Roof Today

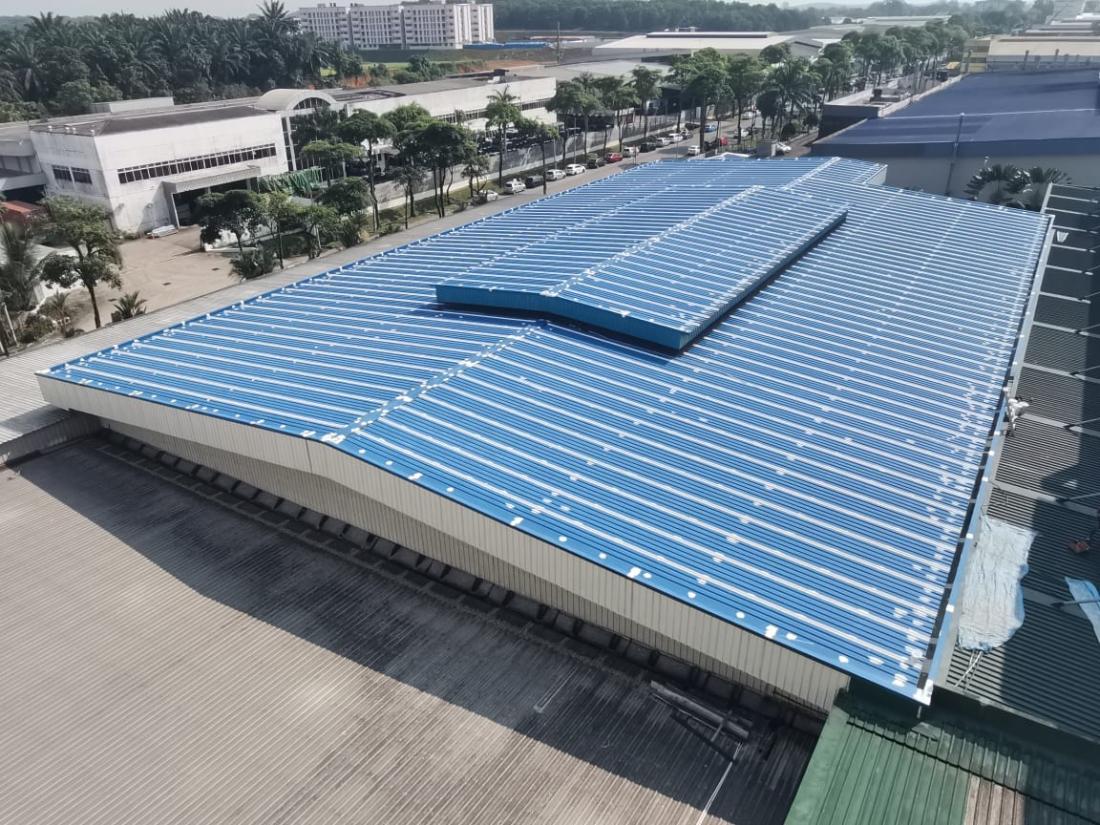

Recently, a major heat reflective roof coating project for metal roof and gutter system in Senai was accomplished. The project highlights the advantages of this specially formulated roof Coating developed in Germany and examines how its impact enhances building efficiency.

Overview

This heat reflective root coating project covered an impressive area of 7,060 square meters, consisting of 6,512 square meters of metal roofing and 548 square meters of gutters. The scale of this project showcases a commitment to delivering quality coating services, leaving clients in Taiwan impressed.Coating on Industrial Roof Building

Building and construction is a hugely challenging industry due to heavy rainfall, intense sunlight, and extreme temperatures. Lack of waterproofing in metal roofs results in serious structural damage, costly repairs, and operational disruptions. Effective roofing solutions that guarantee the life of the building structure are very important.Total Time to Complete

The estimated time to coat the roofs in Senai was about eight weeks from preparation to final inspection. This period has factored in quality and safety throughout the process.Key Stages of the Work

Advantages of Heat Reflective Roof Coating

There are various advantages to the use of Roof Coating in an industrial context:

Safety Precautions

Safety considerations were paramount in every step of this project. This encompassed strict safety practices, such as detailed safety inductions for all operatives and the installation of safety lines in the metal roof to ensure a secure working environment. These good safety records reduce injury risks and add value to overall project efficiency.Client Satisfaction and Long-Lasting Legacy

Quality and customer satisfaction go hand in hand. Repeat business earned from long-standing clients in Taiwan speaks volumes of reliability and experience. This roofing project adds to prestige for the company and sets the standard for projects yet to come.Conclusion

The groundwork, methodology, safety concerns, and work application of the Heat Reflective Coating show a clear route to excellence. This has ensured that protection for industrial customers can be guaranteed in terms of longevity and cost savings. This project also proves its track record of quality and reliability as a leading player in the industry for roof coating and waterproofing. Coatings protect industrial facilities; they are investments in durability and efficiency. It focuses on quality material and an elaborate process to present itself as a reliable partner for enterprises committed to elemental asset protection, setting the highest standard of excellence in quality and safety with excellent customer satisfaction.Feature Company

Roof Coating Applicators and Distributors

TL Terang Sdn Bhd

TL Terang Sdn. Bhd. (abbreviated as TLT) was officially separated from our Mother group and established in 2009. Initially, TLT has played an active role as Main Contractor or Sub-Contractor in the design& build factory; including all forms of earthworks, civil & structural works, plant machinery & equipment installation. With past involvement in civil engineering works, we understand the effect and basis of existing structure problems which require huge funds for maintenance. Conventional maintenance methods often have a short life span and traditional methods always had been an issue for most manufacturers and factory owners. Today, Climate Active Paint ceramic coating is the breakthrough answer to all these problems.

Thus, we have evolved into a specialist in Climate Active Paint® ceramic coating applicator and distributor to cope with these problems. Besides, we are the exclusive distributor in Malaysia, Singapore, and Thailand of Climate Active Paint®ceramic coatings. We have specialized experience in installing thermal insulation, waterproofing, repair & coating for roof, tank coating, exterior & interior wall coating, and more. We are confident with the quality of our work with the past 7-year projects that we have received. This often became the credit for us to build confidence among our clients. However, current achievements will never be enough to satisfy our desire.

As a result, we will strive to fulfill our client's requirements and operate within budget and time frame restraints. In complementing our expertise, we also have the right capabilities to provide project management and engineering services to our potential clients.

Feature Product

Climate Coating | SICC Coatings | Ceramic Coating

ThermoActive Coating | Cool Roof Paint | Roof Coating

ThermoActive is the climatizing ceramic roof coating. It makes for cool rooms under a hot sun. ThermoActive extends the roof structure's lifespan and reduces the building's temperatures. This saves resources for the maintenance of the roof and reduces the energy consumption of the air conditioning systems. The innovative formulation and high-quality raw materials ensure a flexible and reflective membrane with excellent properties is formed after applying the coating. Cost reduction through passive air conditioning The reflective ThermoActive coating absorbs moisture that evaporates through sunlight and cools. The roof does not necessarily have to be coated white. High cooling capacities through evaporation are also achieved with darker shades. In this way, energy consumption for cooling can be reduced in any case and contribute to CO2 reduction. Typically ThermoActive reduces temperature of more than 20 degrees Celsius through its ceramic coating with simultaneous protection against water, corrosion, and the effects of chemicals.